When people start looking for a quality kitchen knife they often have to decide between a Western or Japanese style knife.

Two great brands that fit this question are ZWILLING JA Henckels and Shun.

In this article, I’m going to tell you the differences between these two great brands. I’ll go in-depth into the details of each, talking about where they are made, what materials are used and the difference in price.

This article should provide all the information you need to select the right knife for your needs.

For those with busy family kitchens, the durability and familiarity of a ZWILLING JA Henckels knife would probably be preferable. But for those who are looking for a super sharp knife with a Japanese influenced design then Shun knives are a fantastic choice.

| My recommendation | Current price |

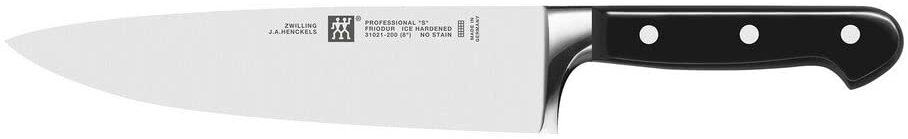

| ZWILLING Professional “S” Chef’s Knife | View on Amazon (opens new tab) |

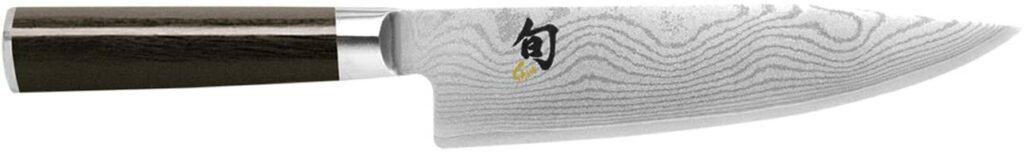

| Shun Classic 8-Inch | View on Amazon (opens new tab) |

ZWILLING JA Henckels vs Shun – Comparison Table

Here is my summary comparison table for each brand. This is mostly based on their main range of knives; the ZWILLING Professional “S” and the Shun Classic.

For a more in-depth look at each category then check out the rest of the article below.

| Category | ZWILLING JA Henckels (Pro S) | Shun |

| Country of Manufacture | Germany | Japan |

| Steel type | X50CrMoV15 | VG-MAX |

| Rockwell hardness | HRC 57 | HRC 61 |

| Factory edge | 15 degrees (double bevel) | 16 degrees (double bevel) |

| Handle material | POM (thermoplastic) | Pakkawood (wood/resin composite) |

| Price range | $140 – $160 (Pro S) | $160 – $180 (Classic) |

| Main benefit | More durable | Sharper |

| My recommendation | Zwilling 8-Inch Professional S (view on Amazon) | Shun 8-Inch Classic (view on Amazon) |

ZWILLING JA Henckels vs Shun – Where are they made

| Brand | Country of Manufacture |

| ZWILLING JA Henckels | Germany |

| Shun | Japan |

ZWILLING JA Henckels knives are produced in the German city of Solingen, where they have been produced since their launch in 1731.

ZWILLING JA Henckels are not to be confused with knives labeled just ‘JA Henckels’. ZWILLING knives are distinctly marked with the logo of the two stick-like people.

JA Henckels knives, without the ZWILLING mark are not made in Germany.

ZWILLING is a huge group, which owns various knife brands. Generally, ZWILLING knives are a mark of quality.

The most well-known brand within the ZWILLING group is JA Henckels, but ZWILLING also owns other more surprising brands like Kramer and Miyabi which are both made in Japan.

All Shun knives are manufactured in the Japanese city of Seki. Seki is known as the knife capital of Japan, with a population of only 90,000 it lies around 150 miles from Toyoko but is the central hub for all of Japan’s major knife manufacturers.

Shun knives are designed with a Japanese influence but to suit the demands of the Western market, with a larger focus on durability compared with other Japanese brands.

Both of these brands produce their knives in the traditional heartlands of their heritage, an added bonus for anyone looking for a genuine German or Japanese knife.

ZWILLING JA Henckels vs Shun – What steel do they use

The steel used in knives will often change depending on which range you pick.

Here I’m going to focus on the most popular range for both ZWILLING JA Henckels and Shun knives.

Here I’m going to focus on the most similar for both ZWILLING and Shun knives. That’s the Professional “S” for ZWILLING and Classic for Shun.

| Brand | Steel type | Rockwell hardness |

| ZWILLING Professional “S” | X50CrMoV15 | HRC 57 |

| Shun Classic | VG-MAX | HRC 61 |

Which steel a knife uses is often the best insight into its influence, and what functionality the brand has placed most focus on.

The ZWILLING Professional “S” range uses X50CrMoV15. This is a German steel that is used for the majority of ZWILLING JA Henckels knives.

It’s popular steel amongst producers of quality western-style knives. That’s because it has a particular focus on durability, whilst retaining enough strength for a sharp edge.

The main elements of interest within X50CrMoV15’s composition are Carbon, Vanadium and Chromium.

The Carbon content is 0.55%. That’s not particularly high when comparing it with other quality knives; however, it’s high enough to provide sufficient strength in the blade for a 15 – 20 degree angle on each side, which is standard for western knives.

The big benefit of not having a very high Carbon content is that higher Carbon steels are usually more brittle, therefore the 0.55% content keeps the blade durable.

That’s the same with the strong Vanadium of 0.4%, Vanadium improves the resistance to wear of the steel also adding to its durability.

The Chromium content is 15% is what the 15 in X50CrMoV15 represents. Chromium is vital for the durability of steel as it’s what makes stainless steel resistant to rust.

Steel need only be 10.5% to be considered stainless, so a 15% content is high and makes this a quality stainless steel, very unlikely to rust unless extremely mistreated by the owner.

The Shun Classic range uses their own Japanese steel VG-MAX. Not all Shun knives are made from VG-MAX.

It’s their own specially formulated steel with the aim of VG-MAX being an improvement on the (already very good) VG-10 steel.

VG-MAX is a fantastic steel. It’s been made with a Japanese influence in mind but also with a strong focus on appealing Western markets.

That means it’s got a fantastic balance between strength and durability.

We can see why when we look at VG-MAX’s levels of Carbon, Vanadium and Chromium.

This is a high-Carbon steel, with a Carbon content of 1.1%. Often, such a high Carbon steel will be more prone to chips in the blade. As materials become harder they usually become more brittle; however, that’s not quite the case for VG-MAX.

To understand why we’ll look at the Vanadium content first. It’s pretty high, at 0.3%, that’s not as high as the ZWILLING’s X50CrMoV15 Vanadium content but for a high Carbon blade, it compares very well.

As a result, VG-MAX is more resistant to wear than most other high Carbon steels.

The Chromium content is higher than X50CrMoV15 at 16%. That makes VG-MAX one of the best stainless steel on the market at resisting rust.

Those two factors make this a very durable high Carbon steel.

The ZWILLING’s X50CrMoV15 steel will still be more durable than the VG-MAX, simply because its Carbon content is so much lower. However, Shun has done a fantastic job of creating a high Carbon knife that is still very durable.

That big difference in Carbon content is clear when we look at the comparative Rockwell Hardness (HRC).

The Shun Classic knives have a much higher HRC than the ZWILLING Professional “S”, standing at 61 compared with 57.

That hardness is reflected in their sharpness, which is what we’ll look at next.

ZWILLING JA Henckels vs Shun – How sharp are they

Once again I’m going to focus on the most popular knives from each brand for this comparison.

You will experience a sharper edge using Shun knives than ZWILLING JA Henckels knives, but to fully understand why will take some description on the details.

| Brand | Factory edge | Rockwell hardness |

| ZWILLING Professional “S” | 15 degrees (double bevel) | HRC 57 |

| Shun Classic | 16 degrees (double bevel) | HRC 61 |

When it comes to sharpness I believe the focus should really be on the hardness of the steel rather than the out-of-the-factory edge angle.

Often people will look at the knife with the smallest angle and say that’s the sharpest, but in practicality, this isn’t quite true.

Harder knives will hold a sharper edge for longer. The Shun uses much harder steel than the ZWILLING JA Henckels, and this is generally true throughout each brand’s range of knives.

Shun uses Japanese steel and that tends to have a focus on hardness, in order to create a sharper edge.

So, even though ZWILLING Professional “S” knives are made with a factory edge of 15 degrees, the Shun knife will actually hold its edge for much longer.

ZWILLING JA Henckels knives will dull much more quickly than Shun knives and to maintain that kind of angle they would have to be sharpened very frequently.

The VG-MAX steel used by Shun would be able to hold an angle of 12 degrees if you wanted to sharpen it to that, but the 15 – 16 degree mark is sensible to prolong the retention of the edge.

In summary, even though the factory edge of the ZWILLING Professional “S” is sharper, the Shun will actually be able to retain its edge for much longer and so during practical use of the knife the Shun will feel like a much sharper blade.

ZWILLING JA Henckels vs Shun – What are the handles made from

The material used for handles is a vital and often overlooked feature of any knife.

A quality handle is often the sign of a quality overall knife. Handles need to be made from a durable material that can withstand all the heat and moisture fluctuations knives can experience in the kitchen.

Once again we’ll focus on the two main ranges from each brand, the ZWILLING Professional “S” and Shun Classic knives.

| Brand | Handle material |

| ZWILLING Professional “S” | POM (thermoplastic) |

| Shun Classic | Pakkawood (wood/resin composite) |

ZWILLING JA Henckels use a thermoplastic material called POM (Polyoxymethylene) for their knife handles.

Materials like these are ideal for knife handles due to their extreme durability.

POM is specifically designed for high stiffness and stability, and being a thermoplastic means it’s also extremely resistant to temperature and moisture changes.

Shun use a wood/resin composite called Pakkawood for their knife handles.

Pakkawood is extremely common in knife handles for quality Japanese knives, although many non-Japanese knife manufacturers around the world have begun to use it as well.

Pakkawood is a great material for knife handles, it’s more dense and durable than real timber. That means it’s more resistant to wear and tear and won’t crack over time as timber handles might.

The versatility of design also makes it a popular choice, it can be dyed in all sorts of colors and will often give the appearance of a true wood finish as it does on the Shun Classic range.

Pakkawood is very resilient to temperature and moisture changes and makes a terrific material of choice, it also adds to the Japanese influence of the knife with Pakkawood being a popular Japanese knife handle material.

Both POM and Pakkawood are top quality knife handle materials and suit the respective German and Japanese heritage of each knife.

ZWILLING JA Henckels vs Shun – How much do they cost

Both these brands have wide ranges of knives all at differing price ranges.

To allow for a fairer comparison I’ve categorized three of their major ranges that represent their highest and lowest cost knives.

I’ve tried to compare similar knives, sticking to 8 Inch Chef’s knives or the closest equivalent they have in the range.

In brackets next to the general price range you’ll see the name of the range.

These prices are rough estimates. Prices do change over time but this is intended as a rough guide.

| Brand range | ZWILLING JA Henckels | Shun |

| Premium | $180 – $200 (Pro) | $200 – $250 (Premier) |

| Standard | $140 – $160 (Professional S) | $160 – $180 (Classic) |

| Value | $80 – $100 (Twin Signature) | $80 – $100 (Sora) |

Overall both ZWILLING JA Henckels and Shun offer a quite similar range of prices for their knives.

Shun knives tend to be slightly more expensive, but then Japanese knives are usually quite a lot more expensive than western ones.

Given that Shun knives are made entirely in Japan, using Japanese materials the price difference is very slim.

I think that’s especially true of the mid-priced ranges for both brands. The VG-MAX steel Shun use really is a brilliant steel, so for the same 8-Inch knife to be of such a similar price bracket is, I would say, very good value.

On balance, both these brands price their respective ranges at similar levels, so which you choose should be more down to what you’re looking for from a knife rather than budget.

ZWILLING JA Henckels vs Shun – What is the difference

Now that we have looked at the design, materials, background and price of these brands we can fully understand the difference, and you should be able to make an informed decision on which knife is correct for you.

The main differences between ZWILLING JA Henckels and Shun knives is the sharpness and durability, created from the steel used and the overall design of each knife.

| Brand | Main benefits |

| ZWILLING JA Henckels | More durable, Western design |

| Shun | Sharper, Japanese design |

The Shun is the sharper blade. It’s a very high Carbon knife at 1.1% Carbon and has great edge retention.

The Shun is also remarkably durable for a high Carbon knife and is certainly one of the most durable Japanese knives available.

However, ultimately ZWILLING JA Henckels knives are purpose built for durability so a high Carbon knife is never going to be as durable as a ZWILLING JA Henckels.

The other major difference is the design. The ZWILLING JA Henckels is a classic Western design, perfect for rock chopping and very familiar to Western cooks.

The Shun is much more Japanese in its appearance. It’s straight, oval handle is typically Japanese and could take some getting used to, although the blade edge has clearly been curved to suit the rock chopping style Western cooks tend to use.

With that understood, it should now be easy to choose between the two knives.

ZWILLING JA Henckels vs Shun– Which is better for you

I have to stress that these are both brilliant knives. There is no clear winner, it’s really down to which one suits your needs the best.

For a busy family kitchen, where multiple people might be using the knife, then I would recommend the ZWILLING JA Henckels.

It’s more durable than the Shun. Don’t get me wrong, Shun Classics are very durable knives, but ZWILLING JA Henckels is one of the most durable brands on the market and any high Carbon knife just won’t match it for durability.

The ZWILLING JA Henckels is also a much more classic western Chef’s knife design which is generally preferable if multiple people will be using it.

If sharpness is what you care about, then the Shun is the best choice for you.

The Shun Classic is a brilliant knife. VG-MAX steel is one of my favorites as, even though it can’t quite compare with the durability of ZWILLING JA Henckels, it is still extremely durable for Japanese high Carbon steel.

As long as you treat a Shun with a reasonable amount of respect then it won’t rust, chip or snap and you will have a razor-sharp edge.

The design of the knife should also be a consideration. Even though they’ve been tailored in many ways for the Western market, Shun Knives are still distinctly Japanese, with that straight, oval-shaped handle.

My ZWILLING JA Henckels Recommendation

View the 8-Inch ZWILLING JA Henckels Pro S on Amazon (opens new tab)

You can’t really go wrong with the ZWILLING JA Henckels Professional S.

The steel is ultra-durable, ideal for busy kitchens and it’s very unlikely to rust or chip.

It uses POM thermoplastic for the handle, so there’s next to no chance of it distorting under the general moisture and temperature fluctuations you get in the kitchen.

It’s a great knife and one of the best examples of a quality western chef’s knife you’ll find.

My Shun Recommendation

View the 8-Inch Shun Classic on Amazon (opens new tab)

The Shun Classic 8-Inch is a superb knife and I’d highly recommend it.

The Shun Classic is an absolute masterpiece of merging Japanese and Western influences and I’d highly recommend it to anyone interested in quality knives that are a bit different.

I don’t think you could be disappointed with this knife.