There’s a change happening in the knife world, and it’s coming from China.

In recent years there has been an influx of Chinese knives that take their influence from Japanese and German styles.

But the thing is, many of these knives are actually receiving a positive response because they use very high-quality materials, Dalstrong is one such brand.

So, let’s see what we get when we compare a traditional German powerhouse like ZWILLING JA Henckels, against the new Chinese brand Dalstrong.

In this article, I’m going to tell you the differences between these two brands. I’ll go in-depth into the details of each, talking about where they are made, what materials are used and the difference in price.

This article should provide all the information you need to select the right knife for your needs.

ZWILLING JA Henckels knives are extremely durable and well suited to busy family kitchens where you need an all-rounder chef’s knife. Dalstrong offers some very sharp knives using Japanese steel but they are not as durable as ZWILLING.

| My recommendation | Current price |

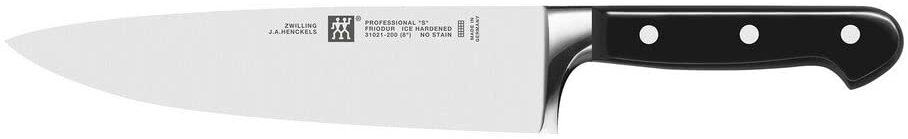

| ZWILLING Professional “S” Chef’s Knife | View on Amazon (opens new tab) |

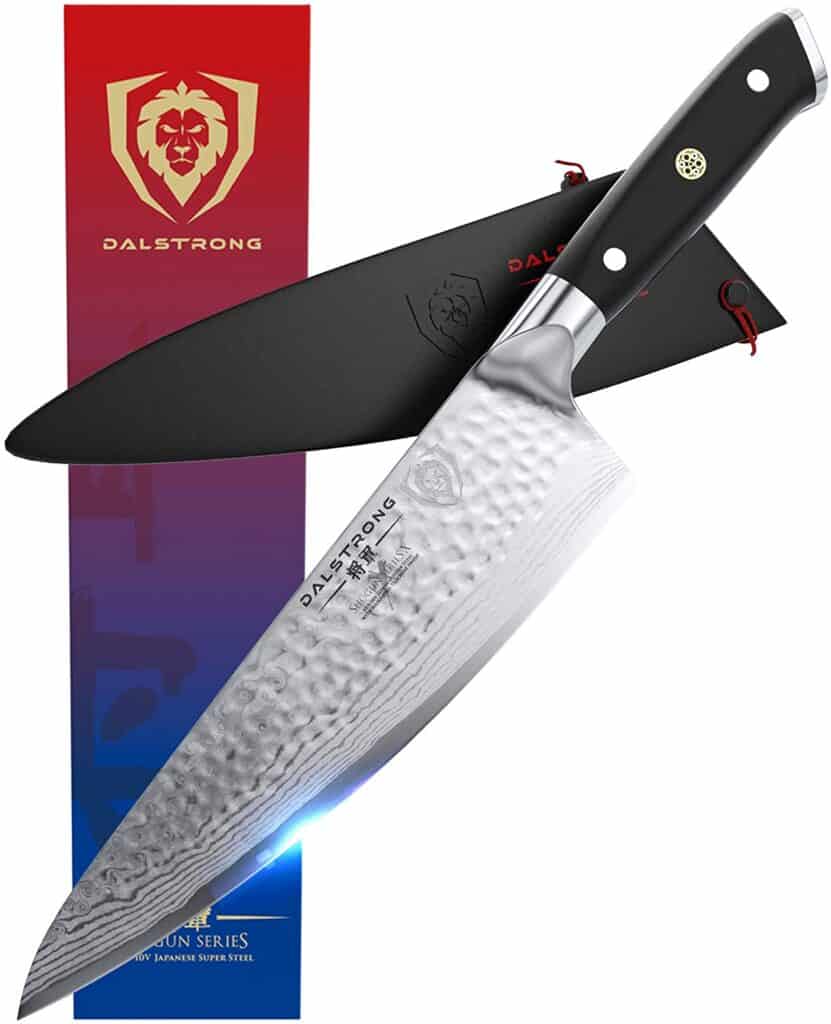

| Dalstrong Shogun Series X Chef’s knife | View on Amazon (opens new tab) |

ZWILLING JA Henckels vs Dalstrong – Comparison Table

Here is my summary comparison table for each brand.

This is mostly based on their most popular knives; the ZWILLING Professional “S” and the Dalstrong Shogun Series X.

For a more in-depth look at each category then check out the rest of the article below.

| Category | ZWILLING JA Henckels (Pro S) | Dalstrong |

| Country of Manufacture | Germany | China |

| Steel type | X50CrMoV15 | AUS-10V (other ranges use AUS-8 and X50CrMoV15) |

| Rockwell hardness | HRC 57 | HRC 62 |

| Factory edge | 15 degrees (double bevel) | 12 degrees (double bevel) |

| Handle material | POM (thermoplastic) | G10 (fiberglass laminate) |

| Price range | $140 – $160 (Pro S) | $125 – $135 (Shogun Series X) |

| Main benefit | More durable, genuine German product | Lower price and sharper |

| My recommendation | Zwilling 8-Inch Professional S (view on Amazon) | Shogun Series X (view on Amazon) |

ZWILLING JA Henckels vs Dalstrong – Where are they made

| Brand | Country of manufacture |

| ZWILLING JA Henckels | Germany |

| Dalstrong | China |

ZWILLING JA Henckels knives are produced in the German city of Solingen, where they have been produced since their launch in 1731.

ZWILLING JA Henckels are not to be confused with knives labeled just ‘JA Henckels’. ZWILLING knives are distinctly marked with the logo of the two stick-like people.

JA Henckels knives, without the ZWILLING mark are not made in Germany.

ZWILLING is a huge group, which owns various knife brands. Generally, ZWILLING knives are a mark of quality.

The most well-known brand within the ZWILLING group is JA Henckels, but ZWILLING also owns other more surprising brands like Kramer and Miyabi which are both made in Japan.

Dalstrong manufactures it’s knives in Yangjiang, China.

On the face of it, the fact that Dalstrong knives are manufactured in China might be a little off-putting.

Let’s be honest, when we see the words ‘Made in China’ we usually think that the quality isn’t going to be great, but with Dalstrong I think there are some large benefits from having production based there.

They still use quality materials, but as the manufacturing costs are kept low these savings are passed onto the customer.

Dalstrong provides a range of both Japanese and German-influenced knives, in this article though I’m mainly focusing on their most popular Japanese style, the Shogun Series X.

ZWILLING JA Henckels is the ‘real-deal’ in regard to being produced directly in the heartland of its German heritage, whilst Dalstrong is definitely less authentic.

That’s the beginning of the differences between these knives, but there are more, starting with the steel.

ZWILLING JA Henckels vs Dalstrong – What steel do they use

Brands often use a variety of steel in their knives which changes between their ranges.

This is particularly true of Dalstrong. They use three different steels throughout their ranges as they have both German and Japanese influenced knives.

Their German series uses X50CrMoV15 (the same as ZWILLING JA Henckels) and their Japanese series use both AUS-10V and AUS-8 depending on the range.

For a fair comparison, I’m going to focus on the most popular range for both ZWILLING JA Henckels and Dalstrong knives.

For ZWILLING JA Henckels that’s their Professional “S” range and for Dalstrong it’s their Shogun Series X range, which uses their best steel AUS-10V.

| Brand | Steel type | Rockwell hardness |

| ZWILLING Professional “S” range | X50CrMoV15 | HRC 57 |

| Dalstrong Shogun Series X | AUS-10V | HRC 62 |

The ZWILLING Professional “S” range uses X50CrMoV15. This is a German steel that is used for the majority of ZWILLING JA Henckels knives.

It’s popular steel amongst producers of quality western-style knives. That’s because it has a particular focus on durability, whilst retaining enough strength for a sharp edge.

The main elements of interest within X50CrMoV15’s composition are Carbon, Vanadium and Chromium.

The Carbon content is 0.55%. That’s not particularly high when comparing it with other quality knives; however, it’s high enough to provide sufficient strength in the blade for a 15 – 20 degree angle on each side, which is standard for western knives.

The big benefit of not having a very high Carbon content is that higher Carbon steels are usually more brittle, therefore the 0.55% content keeps the blade durable.

That’s the same with the strong Vanadium of 0.4%, Vanadium improves the resistance to wear of the steel also adding to its durability.

The Chromium content is 15% is what the 15 in X50CrMoV15 represents. Chromium is vital for the durability of steel as it’s what makes stainless steel resistant to rust.

Steel need only be 10.5% to be considered stainless, so a 15% content is high and makes this a quality stainless steel, very unlikely to rust unless extremely mistreated by the owner.

The Dalstrong Shogun Series X range uses Japanese steel AUS-10V. Other Dalstrong knives use X50CrMoV15 (for their German range) and AUS-8(another Japanese steel).

This is where we start to see the benefits of Dalstrong knives, the materials they use are very good quality, in this case, imported from Japan, but the Chinese manufacturing reduces the cost to the consumer.

AUS-10V is a Japanese steel with a great reputation. It’s a high carbon steel, with a Carbon content between 0.95% – 1.1%.

That means the steel is hard, allowing it to hold a sharper edge for longer.

The Chromium level is also high at 13% – 14.5%. It’s not as good as the ZWILLING but it’s still enough to make AUS-10V a quality stainless steel and therefore very rust-resistant.

The trade-off here is sharpness for durability.

The ZWILLING’s X50CrMoV15 steel is more durable than AUS-10V, the high Carbon Dalstrong knife can hold a sharper edge but it will be more brittle and thus more prone to chipping along the edge.

That hardness is clearly shown in the Rockwell scale score, where the Dalstrong Shogun Series X knives have a much higher HRC than the ZWILLING JA Henckels, standing at 62 compared with 57.

ZWILLING JA Henckels vs Dalstrong – How sharp are they

Once again I’m going to focus on the most popular knives from each brand for this comparison. That’s the ZWILLING Professional “S” and Dalstrong Shogun Series X.

You will experience a much sharper edge using Dalstrong knives than ZWILLING JA Henckels knives. The factory edge is more acute and the steel is significantly harder. ZWILLING JA Henckels knives are primarily focused on durability rather than sharpness.

| Brand | Factory edge | Rockwell hardness |

| ZWILLING Professional “S” | 15 degrees (double bevel) | HRC 57 |

| Dalstrong Shogun Series X | 12 degrees (double bevel) | HRC 62 |

When it comes to sharpness it’s often the angle of the blade that will be advertised, but actually, the hardness of the steel is probably more important.

Often people will look at the knife with the smallest angle and say that’s the sharpest, but in practicality, this isn’t quite true.

Harder knives will hold a sharper edge for longer. Often knives with a larger angle, but harder steel will actually perform better for sharpness than a softer steel with a more acute angle, as soft steel can’t retain an acute angle for long.

With that being said, Dalstrong offers the best of both worlds when it comes to sharpness.

The AUS-10V high Carbon steel has a Rockwell hardness of HRC 62, meaning it can retain a very sharp edge.

Combine that with the razor-sharp 12 degrees out-of-the-factory angle on the blade and the Dalstrong is by far the sharper knife of the two.

Dalstrong uses Japanese steel and that tends to have a focus on hardness, in order to create a sharper edge.

ZWILLING’s X50CrMoV15 steel will not be able to hold a 15-degree edge for very long.

ZWILLING JA Henckels knives will dull much more quickly than Dalstrong knives and to maintain even the 15-degree factory angle they would have to be sharpened frequently.

However; the benefit of using softer steel is that ZWILLING JA Henckels knives will be much more durable. Since the Dalstrong uses a harder steel it will be more brittle.

Combine that with the very acute 12-degree angle and Dalstrong knives will be more prone to chipping along the edge if they are not looked after carefully.

Overall though, this is a clear win for Dalstrong and is probably its best feature.

ZWILLING JA Henckels vs Dalstrong– What are the handles made from

The material used for handles is a vital and often overlooked feature of any knife.

A quality handle is often the sign of a quality overall knife. Handles need to be made from a durable material that can withstand all the heat and moisture fluctuations knives can experience in the kitchen.

Once again we’ll focus on the two main ranges from each brand, the ZWILLING Professional “S” and Dalstrong Shogun Series X knives.

| Brand | Handle material |

| ZWILLING Professional “S” | POM (thermoplastic) |

| Dalstrong Shogun Series X | G10 (fiberglass laminate) |

ZWILLING JA Henckels use a thermoplastic material called POM (Polyoxymethylene) for their knife handles.

Materials like these are ideal for knife handles due to their extreme durability.

POM is specifically designed for high stiffness and stability, and being a thermoplastic means it’s also extremely resistant to temperature and moisture changes.

Dalstrong uses a fiberglass laminate called G10 for their Executive Plus knife handles. Not all Dalstrong knives use G10 but all Dalstrong ranges do use good quality materials for their handles, such as Pakkawood.

G10 is a fiberglass laminate, making it a fantastic material for knife handles.

It has the perfect combination of being extremely lightweight and very tough. It will be able to withstand any of the standard pressure of a kitchen.

Dalstrong use a variety of materials for their handles, not just G10.

But they always use quality materials, such as the Pakkawood used for their Phantom Series, a quality wood/resin material commonly used as a material by traditional Japanese knife manufacturers.

So whichever range of Dalstrong knives you choose, you can be confident that the handle will be a quality, durable and comfortable one.

Both POM and G10 are top-quality knife handle materials so there is little to choose between the two here.

ZWILLING JA Henckels vs Dalstrong – How much do they cost

Both these brands have wide ranges of knives all at differing price ranges.

To allow for a fairer comparison I’ve categorized three of their major ranges that represent their highest and lowest cost knives.

I’ve tried to compare similar knives, sticking to 8 Inch Chef’s knives or the closest equivalent they have in the range.

In brackets next to the general price range you’ll see the name of the range.

These prices are rough estimates. Prices do change over time but this is intended as a rough guide.

| Brand range | ZWILLING JA Henckels | Dalstrong |

| Premium | $180 – $200 (Pro) | $150 – $160 (Omega Series) |

| Standard | $140 – $160 (Professional S) | $125 – $135 (Shogun Series X) |

| Value | $80 – $100 (Twin Signature) | $50 – $60 (Gladiator Series) |

As is clear to see, Dalstrong knives are consistently lower in price than ZWILLING JA Henckels.

Typically Dalstrong’s German-influenced 8-inch Gladiator Series Chef’s knives are around $50 – $60 and their Japanese influenced Chef’s knives are around $130 – $150.

That’s vastly lower than the ZWILLING JA Henckels knives and a lot of the difference is because Dalstrong manufactures their knives in China.

However, their materials are still top quality, their German series uses the same X50CrMoV15 german steel that ZWILLING JA Henckels uses and their Japanese series uses either AUS-10V or AUS-8, both steels that can be found in Japanese knives easily costing over $200.

These steels are all made in either German or Japan and then exported to China for assembly of the knife.

For me, that makes Dalstrong incredibly good value and it justifies the fact they are produced in China.

Frankly, if you found a knife using the same materials as Dalstrong, but manufactured in their heartland (German or Japan), they would easily cost 50% – 100% more than Dalstrong knives do.

So if you’re looking for a quality knife on a budget, Dalstrong is the winner here.

ZWILLING JA Henckels vs Dalstrong – What is the difference

Now that we have looked at the design, materials, background and price of these brands we can fully understand the difference, and you should be able to make an informed decision on which knife is correct for you.

The main difference between ZWILLING JA Henckels and Dalstrong knives is that ZWILLING JA Henckels knives are extremely durable, but Dalstrong knives cost less and their Japanese series are far sharper.

| Brand | Main benefits |

| ZWILLING JA Henckels | More durable, genuine German product |

| Dalstrong | Lower price and sharper |

Dalstrong offers the sharper blade. That’s only the case for their Japanese series but those still cost less than the ZWILLING Professional “S”.

Dalstrong’s German Gladiator series will be relatively similar in sharpness to ZWILLING Professional “S” as they’re made from the same X50CrMoV15 steel. Although the build quality of the Gladiator Series is not as good as ZWILLING, hardly surprising when the price difference is 2 – 3 times.

Dalstrong knives just cost a lot less than ZWILLING JA Henckels.

Their German series tend to be around the $50 mark and their Japanese series are around the $140 mark, both lower than the ZWILLING Professional “S” range and for the quality of materials they use the prices are very low.

ZWILLING JA Henckels knives are purpose-built for durability and they are one of the best brands around at achieving this.

They use classic design and quality durable materials to create a knife that will last, even if it’s not treated particularly well.

But innovative Chinese brands like Dalstrong are beginning to disrupt the market by offering knives made from quality materials at a much lower price.

With that understood, it should now be easy to choose between the two knives.

ZWILLING JA Henckels vs Dalstrong – Which is better for you

I have to stress that these are both brilliant knives in their own way.

There is no clear winner, it’s really down to which one suits your needs the best.

For a busy family kitchen, where multiple people might be using the knife, then I would recommend the ZWILLING JA Henckels.

ZWILLING JA Henckels is one of the most durable brands on the market and there are very few that match it for durability.

If you want a knife that is guaranteed to last, ZWILLING JA Henckels is the best choice. That’s why it’s one of the most popular knives in the world for professional chef’s

If sharpness or budget is your main concern, then Dalstrong is the best choice for you.

The Japanese series of knives Dalstrong offers are made from very high quality and hard steel, so they can retain a much sharper edge than a ZWILLING JA Henckels ever could.

That does mean they are more brittle though. As a result, the edge will be more prone to chipping than the softer ZWILLING JA Henckels, so storing a Japanese series Dalstrong in a knife block or sheath and hand cleaning is a must.

Luckily Dalstrong knives tend to come with a sheath included.

Because they are made in China, Dalstrong knives also cost significantly less than knives using the exact same standard of materials but manufactured in Japan.

This is also true for Dalstrong’s German Gladiator series of knives. They don’t have the benefit of being super-sharp, because they are made with the same X50CrMoV15 as the ZWILLING JA Henckels, but for the quality, they generally cost quite a bit less.

If you’re looking for a quality knife on a budget, go with Dalstrong.

If you are after the best in durability for a busy kitchen, go with ZWILLING JA Henckels.

My ZWILLING JA Henckels Recommendation

View the 8-Inch ZWILLING JA Henckels Pro S on Amazon (opens new tab)

You can’t really go wrong with the ZWILLING JA Henckels Professional S.

The steel is ultra-durable, ideal for busy kitchens and it’s very unlikely to rust or chip.

It uses POM thermoplastic for the handle, so there’s next to no chance of it distorting under the general moisture and temperature fluctuations you get in the kitchen.

It’s a great knife and one of the best examples of a quality western chef’s knife you’ll find.

My Dalstrong Recommendation

View the Dalstrong Shogun Series X on Amazon (opens new tab)

My Dalstrong recommendation would be its most popular knife, the Shogun Series X Chef’s knife.

It’s a hammered Damascus finish using AUS-10V steel, incredible quality when compared with the price.

Since the steel is extremely hard this is a knife you will need to take care of. It has to be stored in a knife block or in a sheath to ensure the blade doesn’t get chipped, and it should be wiped clean and dry after every use.

But if you do that you’ll be rewarded with an incredibly sharp knife for a price that is pretty hard to beat.