Perhaps the single most important factor when choosing a knife is picking one with a good steel.

The quality of the blade is vital to the quality of the knife; however, knowledge of what makes a good steel is not exactly common.

Misleading marketing also makes it difficult to know if a steel is quality or not. So many knives are promoted as ‘High Carbon’ or ‘Quality Stainless Steel’ when the truth is they are hardly anything remarkable at all.

In this article, I’m focusing on what I would regard as the best steel for Chef’s knives.

Which steel is best differs from knife-to-knife. So here I’m not talking about the ‘best ever’ steel, the steel I’m going to talk about is ideal for Chef’s knives in particular and is widely available in quality western-style chef’s knives from various reputable brands.

In my opinion, this is the best ‘all-rounder’ steel for knives, which is exactly what the Chef’s knife needs, since it is used for all manner of tasks.

The best steel for a Chef’s knife is X50CrMoV15. It’s a German steel that is produced with durability in mind. X50CrMoV15 is ideal for Chef’s knives because, out of all the kitchen knife types, Chef’s knives need to be durable since they are the knife that will be used by far the most often.

What makes X50CrMoV15 a good steel for chef’s knives

For anyone who knows a thing or two about knives steel types, they will have heard of X50CrMoV15.

It’s a very popular German steel and in many ways not all that remarkable. There are many Japanese steels that are harder and thus allow a sharper edge.

So some people might be surprised by my choice, but hear me out.

X50CrMoV15 is ideal for Chef’s knives precisely because it’s somewhat unremarkable. It isn’t the ‘best’ at anything but it’s pretty good at lots of things.

It is made for durability, to withstand the pressures of constant use without chipping or rusting.

You can compare it to a 4×4 Land Rover, it’s not the fastest or most powerful car, it’s not flash and it’s not the most expensive, but it’ll grind through tough terrain better than any supercar.

That’s exactly what X50CrMoV15 offers. It’s a tough steel that won’t chip, won’t rust and will last for decades, without being unreasonably expensive.

For me that makes it the ideal steel to use in a Chef’s knife, and it’s the reason most of the most well-renowned Chef’s knife producers use it in their main ranges.

What is X50CrMoV15

X50CrMoV15 is a German steel used by many quality knife brands in their main ranges.

It’s ideal for Chef’s knives because it’s durable and less expensive than many Japanese steels.

The reason for its durability is its chemical composition, essentially the balance of elements that it’s made from.

Composition of X50CrMoV15

This is the chemical composition of X50CrMoV15. However; there are three elements we should focus on; Carbon, Chromium and Vanadium.

| Element | Quantity |

| Carbon | 0.55% |

| Chromium | 15.00% |

| Silicon | 0.80% |

| Manganese | 1.00% |

| Molybdenum | 1.00% |

| Vanadium | 0.40% |

| Phosphorus | 0.02% |

| Sulfur | 0.20% |

Carbon and Vanadium are responsible for making the blade hard and tough. High Carbon knives can take a very sharp edge but are more prone to chipping, the harder they get the more brittle they become.

Many high Carbon Japanese steels will have a Carbon content of 1% or higher. That’s great for a sharp edge but not ideal for durability, as they are much more likely to chip or even snap.

X50CrMoV15 has a Carbon content of 0.55%. That’s high enough to retain an edge between 15 and 20 degrees, pretty much the standard for a western-style Chef’s knife, but not so high that it becomes too brittle.

The high Vanadium content also helps with this. Vanadium improves the resistance to wear of the steel, again increasing its durability.

Chromium is the element that helps steel become rust-resistant, it’s what makes stainless steel.

For steel to be called stainless it only technically needs 10.5% Chromium. The 15% Chromium within X50CrMoV15 makes it a high-quality stainless steel and there are few other knife steels with a higher Chromium content than this.

This all combines to create a knife that is very resistant to rust, wear and tear, chipping and sharp pressure, but that can still hold a good edge of up to 15 degrees.

For a chef’s knife, which is used for so many different food preparation tasks, this kind of versatile is vital.

Chef’s knives using X50CrMoV15

If you’re looking for a Chef’s knife that uses X50CrMoV15 for its blade then I have two recommendations.

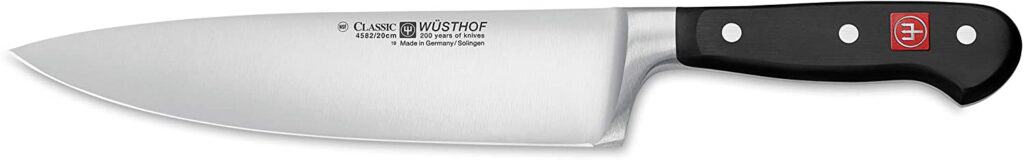

Wüsthof Classic 8-Inch Chef’s Knife

View on Amazon (opens new tab)

Wüsthof are a huge German manufacturer and one of the best makers of classic western chef’s knives.

Their Classic Chef’s knife is perfectly designed, with a great curve to the blade edge allowing for easy rock chopping.

The blade is forged steel and of course, uses X50CrMoV15. It’s full tang into the triple-riveted thermoplastic handle.

I like this knife for many of the same reasons I like X50CrMoV15 steel. It’s made for durability and is an extremely practical knife.

It won’t let you down, it won’t break and it will do everything you need from a Chef’s knife.

This would be my personal recommendation if you’re looking for a Chef’s knife; however, I do have a secondary recommendation if you’re on a tighter budget.

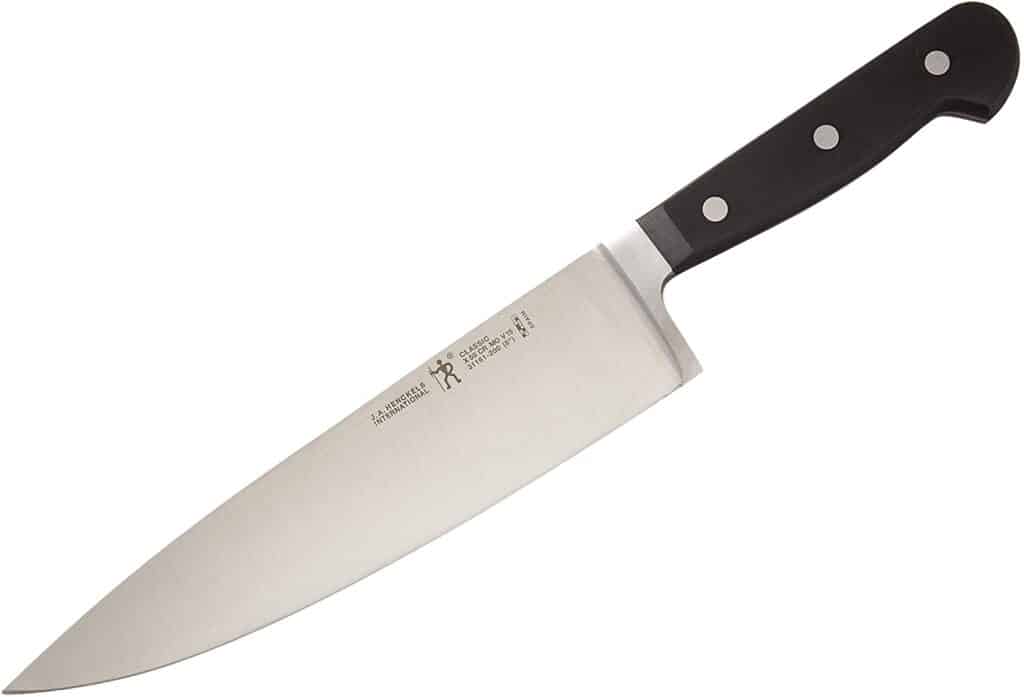

J.A. Henckels Classic 8-Inch Chef’s Knife

View on Amazon (opens new tab)

Zwilling J.A. Henckels are another huge German knife manufacturer and they also use X50CrMoV15 steel.

Their Classic Chef’s knife costs less than the Wüsthof knife above but still uses forged steel with a full tang into a thermoplastic handle.

It’s a great option if you’re on a bit of a budget but still want a hard-wearing Chef’s knife. I prefer the design and slightly better quality of the Wüsthof, but this knife commands a strong second place.